The Dangers of Acid Etched Glass in the Medieval Era

The era of innovation began to take the West out of the dark ages and into a time where every day processes would begin to become easier. While some artisans would continue generational traditions to sustain their livelihoods, the artists who worked with glass – would choose newer, faster, and less dangerous ways in which to achieve the same result. The demand for custom etched glass would undergo a much safer transition from its previous, more dangerous way using hydrofluoric acid to achieve an etched glass result.

Today we’ll discuss how acid etched glass from the Medieval Ages differs from how acid etched glass if produced today.

Glass: A Luxury Material

Fabricating custom etched glass began in the early 15th century. Artists would scratch the surface of hand-blown glass with an acid to create intricate designs, motifs, and ornate imagery. Glass during this time was deemed a luxury item due to the arduous process it took for consistent results. Glass was an exclusive product available for the elite class of the period. You can learn more about the history of glass in our last blog post, where we discuss the origins of glass.

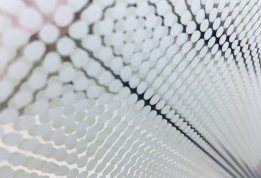

Achieving Etched Glass with Acid

During the Medieval Period, etched glass was achieved using hydrofluoric acid – a highly corrosive and reactive chemical. The chemical reaction resulted in the deterioration of the silica from the glass surface – which achieves the effect of a roughened, frosted glass appearance. The pitfall of using acid to achieve etched glass, is that it would put artisans at risk. In some cases, artisans would become poisoned after inhaling its fumes after brief exposure.

Acid Etched Glass Today

The glass manufacturers and artisans of today still use hydrofluoric acid to achieve the same desired etched glass look. However, the processes adhere to safety standards in order to minimize danger for the artist or manufacturer, i.e. the acid is kept in polyethylene containers which the acid is unable to corrode.

No longer deemed a luxury item, glass and custom etched glass alike are used in a range of applications including interior partitions, railings, shelves, shower and bath enclosures, walls, kitchen cabinet doors, doors, windows, and much more!

Selecting the Right Glass Manufacturer for Your Custom Etched Glass Design

All Team Glass is your go-to for etched glass design in Toronto and the GTA. We utilize a range of techniques to provide our clients with quality glass products for commercial and residential purposes. Our artists are fully capable of bringing your glass design to life! Call us today to learn more about our services!

The era of innovation began to take the West out of the dark ages and into a time where every day processes would begin to become easier. While some artisans would continue generational traditions to sustain their livelihoods, the artists who worked with glass – would choose newer, faster, and less dangerous ways in which to achieve the same result. The demand for custom etched glass would undergo a much safer transition from its previous, more dangerous way using hydrofluoric acid to achieve an etched glass result.

Today we’ll discuss how acid etched glass from the Medieval Ages differs from how acid etched glass if produced today.

Glass: A Luxury Material

Fabricating custom etched glass began in the early 15th century. Artists would scratch the surface of hand-blown glass with an acid to create intricate designs, motifs, and ornate imagery. Glass during this time was deemed a luxury item due to the arduous process it took for consistent results. Glass was an exclusive product available for the elite class of the period. You can learn more about the history of glass in our last blog post, where we discuss the origins of glass.

Achieving Etched Glass with Acid

During the Medieval Period, etched glass was achieved using hydrofluoric acid – a highly corrosive and reactive chemical. The chemical reaction resulted in the deterioration of the silica from the glass surface – which achieves the effect of a roughened, frosted glass appearance. The pitfall of using acid to achieve etched glass, is that it would put artisans at risk. In some cases, artisans would become poisoned after inhaling its fumes after brief exposure.

Acid Etched Glass Today

The glass manufacturers and artisans of today still use hydrofluoric acid to achieve the same desired etched glass look. However, the processes adhere to safety standards in order to minimize danger for the artist or manufacturer, i.e. the acid is kept in polyethylene containers which the acid is unable to corrode.

No longer deemed a luxury item, glass and custom etched glass alike are used in a range of applications including interior partitions, railings, shelves, shower and bath enclosures, walls, kitchen cabinet doors, doors, windows, and much more!

Selecting the Right Glass Manufacturer for Your Custom Etched Glass Design

All Team Glass is your go-to for etched glass design in Toronto and the GTA. We utilize a range of techniques to provide our clients with quality glass products for commercial and residential purposes. Our artists are fully capable of bringing your glass design to life! Call us today to learn more about our services!