3 Classifications of Safety Glass

Whether it’s the fortified glass used for our vehicle windshields, or tempered glass panels in our shower glass enclosures – there’s no denying that safety glass offers both security and aesthetic benefits across a range of everyday applications we rely on. While we may understand that safety glass mitigates potential safety hazards, we likely don’t fully understand the various types of safety glass that exist.

Safety glass is any type of glass that is manufactured to reduce its likelihood of shattering.

In the event that safety glass does break – it is designed to shatter in such a way that does not harm those nearby. “Safety glass” is an overarching term used to describe three categories of fortified glass types. The three glass categories that fall into the overarching classification of safety glass are laminated safety glass, tempered safety glass, and armed glass.

Laminated Safety Glass

Laminated glass is manufactured with a polyvinyl butyral (PVB) inner layer which helps dampen the effect of sharp blows and sound for added soundproofing. Laminated glass can be cut, dawn, or drilled – which is something tempered and armed glass are not capable of withstanding.

The most common use of laminated safety glass is in the passenger windows of vehicles, or in sloping glass roofs.

Tempered Safety Glass

Tempered safety glass is manufactured by heating glass to its melting point and then rapidly cooling it. Similar to the process of producing fortified concrete through stressing, the tempered glass manufacturing method allows the glass to retain enhanced strength once cooled down, and in the event that the tempered glass panels are shattered – produces granulated instead of the sharp-cutting shards of standard glass.

Common applications of tempered glass panels are in commercial building windows and doors, shower and tub enclosures, fireplace screens, and oven/stove-top surfaces.

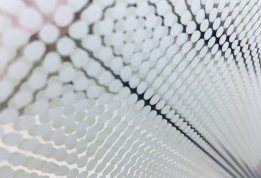

Armed Glass

Armed glass (also known as wired glass) is manufactured with a metal grill that functions to strengthen the glass. The metal grill is similar to chicken wire in appearance, and helps to hold the glass in place. Due to the grill layer, transparency is reduced.

Armed glass is commonly used as roofing on factory and other industrial-type buildings, as a way to slow the spread of fires.

Whether it’s the fortified glass used for our vehicle windshields, or tempered glass panels in our shower glass enclosures – there’s no denying that safety glass offers both security and aesthetic benefits across a range of everyday applications we rely on. While we may understand that safety glass mitigates potential safety hazards, we likely don’t fully understand the various types of safety glass that exist.

Safety glass is any type of glass that is manufactured to reduce its likelihood of shattering.

In the event that safety glass does break – it is designed to shatter in such a way that does not harm those nearby. “Safety glass” is an overarching term used to describe three categories of fortified glass types. The three glass categories that fall into the overarching classification of safety glass are laminated safety glass, tempered safety glass, and armed glass.

Laminated Safety Glass

Laminated glass is manufactured with a polyvinyl butyral (PVB) inner layer which helps dampen the effect of sharp blows and sound for added soundproofing. Laminated glass can be cut, dawn, or drilled – which is something tempered and armed glass are not capable of withstanding.

The most common use of laminated safety glass is in the passenger windows of vehicles, or in sloping glass roofs.

Tempered Safety Glass

Tempered safety glass is manufactured by heating glass to its melting point and then rapidly cooling it. Similar to the process of producing fortified concrete through stressing, the tempered glass manufacturing method allows the glass to retain enhanced strength once cooled down, and in the event that the tempered glass panels are shattered – produces granulated instead of the sharp-cutting shards of standard glass.

Common applications of tempered glass panels are in commercial building windows and doors, shower and tub enclosures, fireplace screens, and oven/stove-top surfaces.

Armed Glass

Armed glass (also known as wired glass) is manufactured with a metal grill that functions to strengthen the glass. The metal grill is similar to chicken wire in appearance, and helps to hold the glass in place. Due to the grill layer, transparency is reduced.

Armed glass is commonly used as roofing on factory and other industrial-type buildings, as a way to slow the spread of fires.